Isuzu sewage truck is a new type of sanitation vehicle that integrates sludge and sewage collection, transfer, cleaning and transportation to avoid secondary pollution. Isuzu sewage truck can be self-priming and self-discharging, with fast working speed, large capacity and convenient transportation. Isuzu sewage truck is suitable for collecting and transporting liquid materials such as feces, mud, crude oil and so on. Isuzu sewage truck uses a vacuum pump with large suction power and long suction range. It is especially suitable for the suction, transportation and discharge of sewer sediment, especially large objects such as sewer mud, silt, stones, bricks and so on.

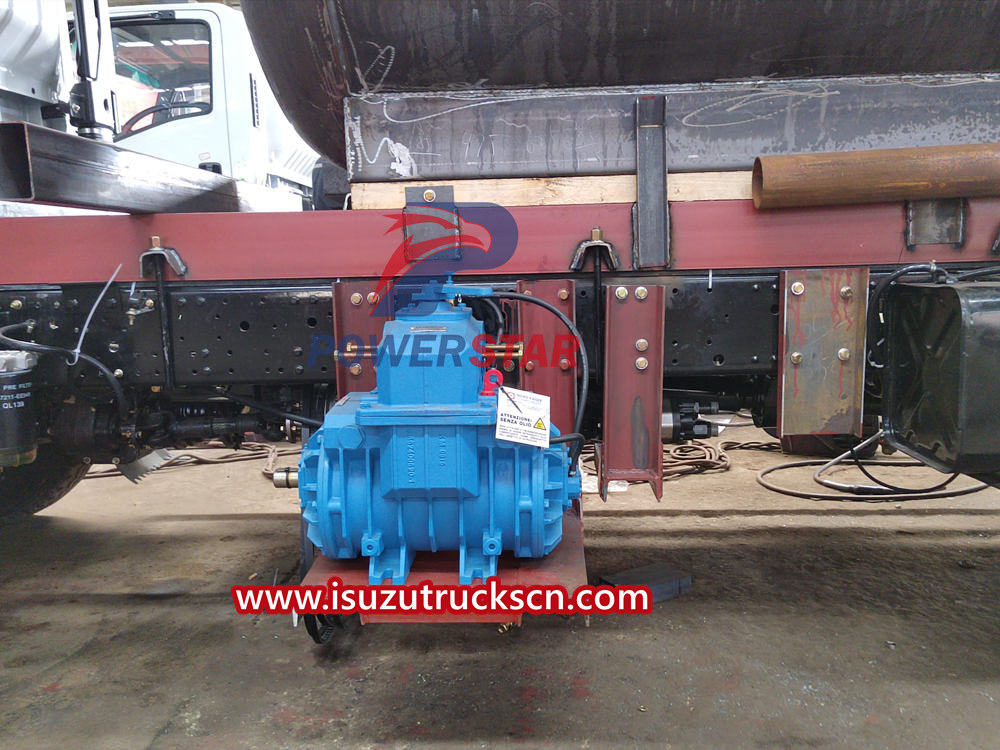

The special part of Isuzu sewage truck is composed of power take-off, transmission shaft, vacuum suction pump, pressure tank, hydraulic part, pipe network system, vacuum pressure gauge, feces viewing window, hand washing device, etc. The vehicle is equipped with high-power vacuum suction Pump and high-quality hydraulic system, the tank head is die-cast in one step, the tank can be opened backwards, and the double top is self-unloading. The dirt in the Isuzu sewage truck tank can be poured directly through the back cover. It has the characteristics of high vacuum degree, large tonnage, high efficiency and wider use.

1. Pre-start inspection and preparation

1). Check whether the engine oil, diesel, hydraulic oil, battery, tires, instruments, lights, etc. are normal, and check whether the safety facilities are complete.

2). Move the rear of the Isuzu sewage truck as close to the operating point as possible and park.

3). Open the side door of the walking platform box, take out the fecal suction hose, and swing it backward without bending.

2. Start operation

1). Pump the water suction hose into the liquid level as deep as possible, ensuring that the pipe end is always 300mm below the liquid level during operation.

2). Push the handle of the four-way valve until it is perpendicular to the ground.

3). Put the transmission into neutral, then start the engine, disengage the clutch, pull the power take-off switch back to put it into gear, and the vacuum pump starts running.

4). The operator should pay attention to monitor the situation near the inlet of the suction hose and use appropriate tools to block debris to avoid blockage.

5). The operator can pass the observation mirror on the top of the rear head. When the liquid level reaches the middle of the observation mirror, the driver should be notified, and colleagues should quickly pull the fecal suction hose off the ground or close the four-way valve. Under normal circumstances, the buzzer will emit an audible and visual signal at this time. When the driver receives the signal, he should reduce the throttle, push the power take-off switch forward and out of gear, the vacuum pump will stop rotating, and press the buzzer switch to cut off its power supply. .

6). Close the fuel tank straight-through cock handle plate parallel to the axis of the inlet mailbox.

7). After flushing the hose, put it back into the walking platform box, close the side door, and make the boom face above the cab.

8). Close the anti-overflow valve and make its handle perpendicular to the road axis.

9). Drive the Isuzu sewage truck away from the work site.

3. Shutdown operation

1). Direct the water-absorbing hose into the sewage tank.

2). Pull the rear handle of the four-way valve parallel to the ground and open the anti-overflow valve until its handle is parallel to the axis of the pipeline.

3). Put the transmission into neutral gear, then start the engine, disengage the clutch, pull the power take-off switch back to put the power take-off into gear, and the vacuum pump starts to run. Put the transmission into neutral gear, then start the engine, disengage the clutch, and put the power take-off into gear. Pull the vacuum switch backward to take power, and the vacuum pump starts to run.

4). After the liquid in the tank is drained, the driver should promptly push the power take-off handle forward to disengage the gear and stop the vacuum pump.

5). Close the fuel tank straight-through cock handle plate parallel to the axis of the inlet mailbox. After flushing the hose, put it back into the platform box, close the side door, and make the boom face upwards of the cab.

6). Drive the sewage suction truck away from the operation site.

4. Maintenance

1) Routine maintenance is carried out by the driver himself. The driver should perform routine maintenance before leaving the vehicle, while driving and after parking once a day.

2) First-level maintenance is performed once a month, focusing on cleaning, lubrication, and tightening.

3) Second-level maintenance, once every quarter, is in addition to the first-level maintenance work and mainly focuses on inspection, anti-corrosion and adjustment.

5. Things to note

1). In order for the Isuzu vacuum tanker vacuum pump to work, you must first understand its working principle. The most important thing in the working principle is the source of power and the consideration of stability. The vacuum pump is powered by the chassis engine. The engine is transmitted to the vacuum pump through the gearbox, power take-off, and drive shaft. During the sewage suction operation, the vacuum pump draws out the air in the sealed tank to form a negative pressure, and uses the atmospheric pressure outside the tank to press the sewage into the tank through the sewage suction pipe. When discharging sewage, the vacuum pump pushes the atmospheric pressure outside the tank into the tank, and uses air pressure to discharge the dirt out of the tank (the continuous working time of the vacuum pump generally does not exceed 30 minutes).

2). The flow sequence of the air flow in the air path is: when suctioning sewage, the vacuum pump sucks the air with a certain humidity in the tank into the water-gas separator, where the water is separated and flows back into the tank, and the gas passes through the four-way along the pipeline. valve into the vacuum pump inlet. It is mixed with lubricating oil in the pump and discharged from the exhaust port through the compression chamber. In particular, the mixture is initially separated through the coarse filter, and the separated oil flows back to the oil pump. The mixed gas is further separated by the oil and gas separator, and then enters the four-way valve and is discharged into the atmosphere. The direction of air flow can be changed by manually operating the four-way valve, allowing for free suction and discharge.

3). After each operation of the Isuzu sewage truck vacuum pump is completed, corresponding inspection work for the sewage suction truck must be made according to the different work intensity to ensure the working life and second working efficiency of the Isuzu sewage truck.