Isuzu mixer truck is a special transport vehicle that is specially used to mix cement, sand, gravel and other raw materials into concrete. Isuzu mixer truck is widely used in construction sites, road construction and other engineering sites. Isuzu mixer trucks can prepare concrete on-site according to the needs of the construction site, reducing the waste of raw materials and losses during concrete transportation and improving construction efficiency. This article will introduce in detail the construction principles of Isuzu mixer trucks.

1. Mixing drum

The core component of Isuzu concrete mixer truck is the mixing drum. The mixing drum is composed of a cylinder, a front end cover, a rear end cover, a spiral blade, a feed port, a discharge port, a feeding auxiliary device and other components. The mixing drum is made of high-strength steel plate and processed by bending, automatic submerged arc welding and other processes. The cylinder has high strength, wear resistance, corrosion resistance, good sealing performance, and can adapt to harsh working environments. The spiral blades are made of high-strength and wear-resistant alloy steel. The arrangement and angle of the blades are reasonably designed to better mix concrete while ensuring the quality of the concrete.

2. Feeding and discharging system

The feeding system consists of a feeding port, a feeding auxiliary device and other components. The location of the feed inlet is reasonably set to ensure the uniformity and stability of the concrete entering the mixing drum. The feeding auxiliary device includes feeding hoppers, feeding troughs and other components, which can help concrete enter the mixing drum and improve the efficiency of feeding. The Isuzu mixer truck discharging system consists of a discharging port, discharging auxiliary device and other components. The location of the discharge port is reasonably set to ensure that the concrete flows out of the mixing drum smoothly. The discharging auxiliary device includes a discharging hopper, a discharging chute and other components, which can help the concrete flow out of the mixing drum and improve the efficiency of discharging.

3. Hydraulic system

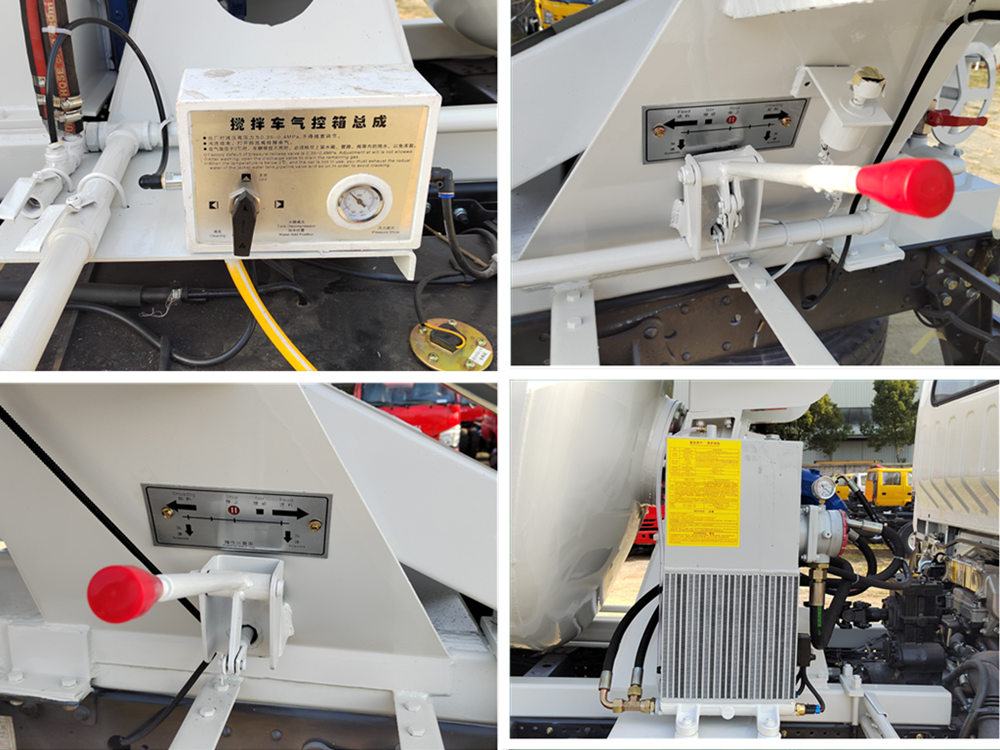

The hydraulic system of Isuzu mixer truck consists of hydraulic pump, hydraulic motor, hydraulic oil tank, hydraulic oil pipe, hydraulic valve and other components. The hydraulic system can control the rotation and tilt of the mixing drum to fully mix the concrete in the mixing drum. The working principle of the hydraulic system is that the hydraulic pump sends hydraulic oil to the hydraulic motor, and the hydraulic motor converts the hydraulic oil into mechanical energy to drive the rotation and tilt of the mixing drum.

4. Control system

The control system of Isuzu concrete mixer truck consists of console, electrical components, sensors and other components. The control system can control and monitor various components of the mixer truck to ensure the safe and stable operation of the mixer truck. The working principle of the control system is to send instructions through the console, and the electrical components convert the instructions into electrical signals and transmit them to the controller of each component. The controller controls the operation of the corresponding components according to the instructions, and at the same time, the sensor feeds back the status of each component to console.

5. Thermal insulation system

The insulation system consists of insulation materials, heaters and other components. The thermal insulation system can ensure the temperature stability of the Isuzu mixer truck during transportation and prevent the solidification and agglomeration of concrete. The working principle of the thermal insulation system is to install thermal insulation materials inside the mixing drum, and the heater can maintain the inside of the mixing drum at a certain temperature to keep the concrete in a flowing state.

To sum up, the construction principle of the Isuzu concrete mixer truck is that through the cooperation of the mixing drum, feeding system, discharging system, hydraulic system, control system, insulation system and other components, the raw materials can be fully mixed to make high-quality concrete. At the same time, the Isuzu concrete mixer truck has the advantages of simple structure, convenient operation, and high efficiency, and can meet the concrete mixing needs of various engineering projects.