3 cbm septic pump truck body parts

This 3000-liter capacity suction truck is designed for small operations. Equipped with an efficient pump system, it can easily collect, transport and unload sewage, sludge and solid waste. It is suitable for sewage treatment and waste management tasks in residential communities, rural environments and small industrial sites. Its compact design and reasonable capacity make it a clean, convenient and versatile sanitation solution.

Work capacity:

3000litersRemarks:

Moro PM60A3 cbm septic pump truck body parts also called 3 cbm septic tanker truck parts,3000L septic suction truck tanker body,3000 liters vacuum truck tanker body kits,3cbm sewage tank body components.3CBM septic pump trucks are indispensable vehicles in the sanitation industry, designed to efficiently collect, transport, and dispose of sewage and other liquid waste materials. The truck body, often referred to as the "upper body" or "superstructure," is a complex assembly of various components that work in harmony to ensure the truck's functionality and efficiency.

This 3 cbm septic pump truck body parts integrates an efficient vacuum suction system and a 3-cubic-meter large-capacity tank, which is specially designed for cleaning complex environments such as septic tanks and sewers. It is made of corrosion-resistant and high-strength materials to ensure long-term stable operation. The vacuum pump is powerful and can quickly suck away dirt and sewage. At the same time, the internal wave-breaking plate design of the tank effectively reduces shaking and improves driving safety. The rapid sewage discharge system combined with the hydraulic lifting function makes the sewage discharge process more convenient and efficient. The overall design is compact and reasonable, and the operation is easy. It is an ideal choice for urban environmental sanitation maintenance, sewage treatment plants and other places.

Specifications

|

3 cbm septic pump truck body parts |

||

|

Tanker Description |

||

|

Tanker |

Capacity |

3cbm |

|

Material |

6mm thickness, high quality carbon steel |

|

|

Structure |

Welding, vacuum tank, Cylindrical |

|

|

Hydraulic lift cylinder to lift up the tank body to outlet the sludge in 45 degree with safety support. |

||

|

Pump |

Type |

MORO PM60A vacuum pump |

|

Free air capacity |

7200 Lt/min(254cfm) |

|

|

Maximum Air Flow @ 18 inHg (inches of Mercury) |

220cfm |

|

|

Max. Vacuum |

28Hg (in.) |

|

|

Max. Pressure |

29psig |

|

|

Power required at max vacuum |

12.2/9HP/Kw |

|

|

Power required at max. pressure |

24.5/18HP/Kw |

|

|

Rotation speed |

1100rpm |

|

|

Max Speed |

1400rpm |

|

|

Working Speed |

1000-1100rpm |

|

|

Oil consumption |

180Gr/h |

|

|

Noise Level |

75dB-A |

|

|

Hose |

3in |

|

|

Continuous vacuum |

18Hg (in.) |

|

|

Features |

High efficient, |

|

|

Pipe |

Wire strengthened hose |

|

|

Special function |

(1) Vertical suction ≥ 7m. (2) Intake and exhaust diameter: 50mm. (3) Full tank pumping time ≤ 4min. (4) Sewage tank emptying time ≤ 4min. |

|

|

Standard configuration |

Equipped with PTO, gear pump,multi-way valve,hydraulic cylinders,hydraulic oil tank,drive shaft,Inspect window,discharge valve,cleaning apparatus,5 meter long suction pipe,oil-water separators,overflow valve,etc. |

|

|

Optional configuration |

Tanker material: stainless steel. |

|

Applications

The 3CBM septic pump truck body is a vital component mounted on a chassis, designed to handle the crucial task of wastewater management. Comprising several intricate parts that work harmoniously, this system plays a pivotal role in sanitation infrastructure, ensuring efficient waste disposal and environmental cleanliness.Here are its main components:

1. Tank Assembly

The tank is the core component of the septic tank pump truck body and has a capacity of 3 cubic meters (CBM). It is made of durable materials such as carbon steel and is designed to withstand the corrosiveness of sewage and the harsh conditions of its operating environment. The tank body is usually equipped with baffles and partitions to optimize fluid dynamics during transportation, prevent sloshing and ensure road stability.

Tank material: high-quality carbon steel with corrosion-resistant coating.

Capacity: 3CBM, enough to handle moderate amounts of sewage.

Design: cylindrical, with optimal capacity and easy cleaning.

3cbm septic pump truck body parts

2. Vacuum Pump System

The vacuum system is an integral part of the septic tank pump truck function and is responsible for extracting wastewater from septic tanks, cesspools and other containers. The system consists of a high-powered vacuum pump, hoses and valves that generate the suction required to drain liquids and sludge from the source into the tank assembly. The efficiency and suction of the vacuum system are key factors in timely and thorough removal of wastewater, minimizing downtime and maximizing productivity.

Pump type: Moro PM60A high-performance vacuum pump.

Power source: Diesel engine, providing reliable and stable power.

Suction: High suction and long suction range, suitable for various sewage types.

3 cbm septic tanker truck parts

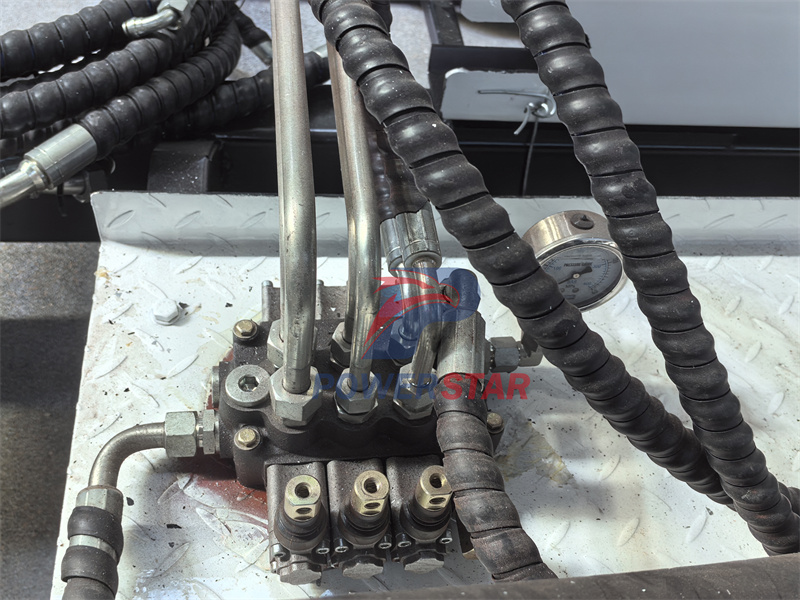

3. Hydraulic system

The hydraulic system powers various mechanisms on the septic tank pump truck, including the lifting and tilting of the water tank, the operation of the suction and discharge valves, and the movement of the suction hose. It consists of a series of pumps, cylinders, valves and hoses, which work together to ensure smooth and efficient operation. Through hydraulic actuators and control mechanisms, operators can manipulate the water tank position, adjust the pump speed and adjust the pressure level to effectively adapt to different wastewater collection scenarios.

Components: Hydraulic pumps, cylinders, valves and hoses.

Function: Provide power for the lifting, tilting and other movements of the truck body.

Advantages: Provide precise control and high torque for heavy-duty applications.

3000L septic suction truck tanker body

4. Pipes and valves

Connecting the vacuum pump system with the tank and other system components is the piping and valve assembly, including a network of pipes, fittings and control valves to regulate the fluid flow, pressure level and operation sequence in the septic tank pump truck body. By strategically positioning pipes and valves to direct fluid flow, operators can effectively manage waste transfer, tank filling, and system draining, ensuring seamless operation and efficient waste treatment throughout sanitation activities.

3000 liters vacuum truck tanker body kits

5. Filtration and treatment mechanisms

To facilitate the separation of liquids and solids in wastewater, septic tank pump truck bodies feature powerful filtration and treatment mechanisms. Combining filters, screens, and separators, these components ensure that only liquid waste enters the tank assembly, while solids and debris are contained or diverted for proper treatment. By maintaining the integrity of the collected wastewater and preventing clogging or damage to the pump system, these filtration components help extend the life and efficiency of the septic tank pump truck.

3cbm sewage tank body components

6. High-pressure cleaning system

An important feature of the septic tank pump truck body is the high-pressure cleaning system, which utilizes a combination of water pumps, nozzles, hoses, and control mechanisms to produce intense water jets at adjustable pressure levels. These high-velocity water streams effectively remove dirt, grease, and other contaminants from surfaces, pipes, and tank interiors, restoring them to a clean and functional state. By strategically directing the water jets, operators can target specific areas for cleaning, ensuring comprehensive sanitation and maintenance of the entire septic tank pump truck body.

Hydraulic cylinder

Hydraulic cylinder

The upper part of the 3-cubic-meter suction truck is its core functional component, which is mainly used to clean up dirt and sewage in septic tanks, sewers, sewage treatment plants and other places.

Main functions

1. Efficient sewage suction:

The upper part of the 3-cubic-meter suction truck is equipped with a high-power vacuum suction pump, which can generate a strong negative pressure to quickly suck dirt and sewage into the tank.

The reasonable design of the suction pipeline can ensure that the dirt is smoothly sucked into the tank to avoid blockage and leakage.

Secondary filter

Secondary filter

2. Dirt storage:

The tank has a volume of 3 cubic meters and can store a large amount of dirt and sewage.

A wave-breaking board is installed inside the tank to reduce the shaking of the liquid during driving and ensure driving safety.

3. Rapid sewage discharge:

There is a sewage discharge port at the bottom of the tank to facilitate the discharge of sewage.

When discharging sewage, the external air can be sucked into the tank by adjusting the four-way valve to increase the pressure in the tank to achieve the effect of rapid sewage discharge.

Hydraulic valve

Drain valve

Locking device

Ladder