ISUZU vacuum sewage truck is a special vehicle that uses the principle of vacuum negative pressure to suck feces and liquid waste into a vehicle-mounted storage tank to containerize feces collection and reduce secondary pollution. The vehicle is mainly used for the suction, transportation and discharge of sludge, feces or sewage in petrochemical plant sewage tanks in sewers, rainwater wells, inspection wells, septic tanks and various ditches.

Work capacity:

5000 LitersTruck model:

PT5050GXWEngine power:

190 HPEngine type:

4HK1-TC51Axle drive:

4×2Gear box:

MLD 6-speed manualRemarks:

Customized design, Italy BP vacuum pump

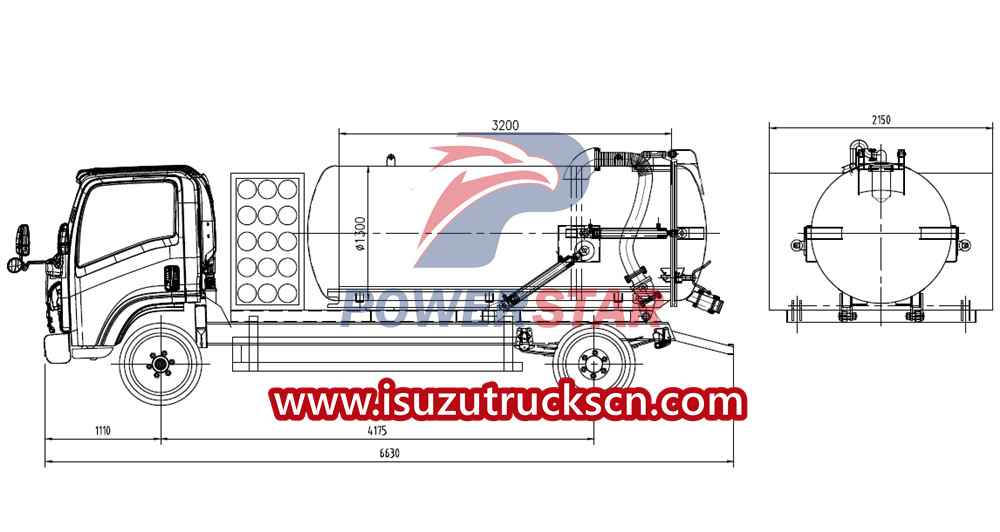

The main structure of the ISUZU septic suction truck includes the chassis, tank, sub-frame, vacuum pump, anti-overflow valve, view tube, piping system and other parts. The tank is the main structure used to store sewage and is usually welded with high-quality steel. The subframe is a structural component that connects the tank body to the vehicle chassis and is fixed by welding or bolting. The vacuum pump is a key component in generating negative pressure, which can pump sewage in and out of the tank. The anti-overflow valve is designed to prevent sewage from entering the vacuum pump and is usually installed on the top of the tank. It is a one-way valve device with a float. It is connected to the suction port of the pump. When the vacuum tank is almost full, the suction port is closed through the joint action of the float and vacuum suction, effectively preventing sewage and dirt from entering the vacuum pump pipeline and the pump. The view tube is a detachable transparent tube used to observe the sewage level in the tank. The pipeline system includes sewage suction pipes and drainage pipes, which are used to connect the tank and the sewage outlet to realize the transportation of sewage.

Our Isuzu vacuum sewage trucks have adopted a variety of measures to ensure safety during the sewage suction process. The vehicle is equipped with a well-known Italian brand vacuum pump, which provides sufficient suction power to make the sewage suction process more efficient and reliable, and can effectively absorb various solid and liquid wastes. The vehicle is also equipped with safety protection devices, such as vacuum pressure gauges, suction pipe pressure gauges, switches, etc., which can promptly alarm or shut down the machine when abnormal conditions occur to protect the safety of operators. In addition, Isuzu sewage sucker trucks also pay attention to the humanization of the design, such as using high-power sewage suction pumps and high-quality hydraulic systems to make the sewage suction process more efficient and reliable; at the same time, the height and position of the sewage outlet have also been carefully designed and adjusted, convenient for operator use and safety.

Product Specifications

|

ISUZU Septic Suction Truck Technical Specifications |

||

|

Product Name |

ISUZU Vacuum Sucker Truck |

|

|

Chassis Model |

QL1100A8 |

|

|

Cabin |

NPR/NQR |

|

|

Whole Vehicle |

Overall dimensions (LxWxH) |

6500*2300*2600 |

|

Wheelbase |

4175 |

|

|

Min. ground clearance |

210 |

|

|

Weight data (kg) |

G.V.W |

11000 |

|

Curb weight |

5600 |

|

|

Max payload |

6000 |

|

|

Whole vehicle |

Max. speed (km/h) |

95 |

|

Max. slope of climb (%) |

30 |

|

|

Engine |

Model |

4HK1-TC51 |

|

Fuel type |

Diesel |

|

|

Maximum power |

190HP |

|

|

Number of cylinders |

4 |

|

|

Displacement (ml) |

5193 |

|

|

Emission standard |

Euro 5 |

|

|

Gear box |

Model |

MLD, manual |

|

Number of gears |

6 forward gears & 1 reverse |

|

|

Axle |

Front Load capacity (ton) |

4 |

|

Rear Load capacity (ton) |

7 |

|

|

Steering Wheel |

left/right hand drive |

LHD |

|

Brake system |

Service brake |

Air braking |

|

Electric device |

Rated voltage |

24V |

|

Tyres & Quantity |

235/75R17.5 |

6+1 |

|

Superstructure Specifications |

||

|

Tank |

Material: high quality carbon steel |

|

|

Capacity(L) |

5000 |

|

|

Material |

Carbon steel |

|

|

Thickness |

6mm |

|

|

Pump |

Type |

Rotary blades vacuum pump |

|

Brand |

Battioni Pagani (BP) |

|

|

Model |

MEC6500 |

|

|

Flow rate (L/min) |

74.8 |

|

|

Speed(r/min) |

1400 rpm |

|

|

Pressure |

204 bar |

|

|

Features |

Simple structure, convenient maintenance, high efficiency, energy saving and reliable operation |

|

|

Hose |

10m suction and discharge pipe |

|

|

Special function |

Suction time ≤ 5min, |

|

|

Equipment |

Equipped with power take off, transmission shaft, sewage tank, pipelines, hose for suction and discharging, fittings, valves |

|

|

Hydraulic open and lock rear cover, vacuum pump, liquid level alarm |

||

Product Structure

Isuzu vacuum pumper truck mainly consists of the following components:

1. Truck chassis: As the foundation and support of the entire vehicle, it provides power and transportation functions.

2. Power take-off: used to obtain power from the car chassis and transmit it to the vacuum sewage pump through the transmission shaft.

3. Drive shaft: used to transmit power to the power take-off and vacuum pump to ensure the normal operation of the equipment.

4. Tank: used to store and treat sewage and dirt, usually with anti-corrosion and anti-leakage features.

5. Vacuum pump: used to generate negative pressure to suck sewage and dirt into the tank. It is usually a high-power, high-vacuum pump.

6. Pipe network system: including sewage suction pipes and drainage pipes, used to connect sewage outlets and sewage suction tanks to realize the transportation of sewage.

7. Vacuum pressure gauge: used to monitor the vacuum degree and pressure changes during the suction process to ensure the normal progress of the suction process.

8. Observation tube: used to observe the liquid level of sewage in the tank.

9. Anti-overflow valve: used to prevent sewage and dirt from entering the vacuum pump and pipelines.

Product Features

The main features of Isuzu vacuum sewage trucks include:

1. Carry out sludge and sewage suction operations under high vacuum conditions. The vacuum pump can self-prime and self-discharge, the sewage suction tank can self-unload hydraulically, and the back cover can be opened hydraulically.

2. Equipped with Italian BP vacuum pump, with high vacuum degree and long suction range.

3. Widely used in sanitation, municipal administration, chemical industry, factories and mines, property management communities, etc. in large, medium and small towns.

4. It is easy to operate and can achieve efficient and fast cleaning and desilting work.

5. Can effectively avoid secondary pollution and protect environmental sanitation and human health.