Isuzu KV100 6cbm compression garbage truck,Its design is modern and simple, and its structure is sturdy and durable. It adopts advanced compression technology, equipped with intelligent operating system and perfect safety system. It is powerful, environmentally friendly and energy-saving, easy to operate, stable and reliable. It can be widely used in the field of urban garbage disposal and is a green and environmentally friendly tool that has attracted much attention.

Work capacity:

6cbmTruck model:

PT5070GXZEngine power:

120HPEngine type:

4KH1CN6LBAxle drive:

4X2,LHDGear box:

MSB 5-speed,manualRemarks:

6CBM garbage boxI. PRODUCT Overview

Trash compactor made by Isuzu trucks also called Isuzu KV100 6cbm trash compactor truck,Isuzu truck with garbage compactor bodies,Isuzu 6cbm rear loader compactor truck,Isuzu KV100 waste collection truck,Isuzu 6cbm garbage disposal truck.

Trash compactor made by Isuzu trucks are an efficient and environmentally friendly garbage collection and transportation vehicle designed for urban sanitation work. It adopts advanced compression technology and automatic control system, which can compress garbage efficiently, thereby increasing loading capacity and transportation efficiency. The vehicle is equipped with high-strength garbage bins and compression mechanisms, ensuring the durability and reliability of garbage disposal. At the same time, the vehicle also adopts environmentally friendly materials and advanced sealing technology to effectively prevent garbage leakage and odor emission, reducing pollution to the environment.

In addition, Isuzu KV100 6 cubic compression garbage truck also has the characteristics of easy operation, one-button control, and humanized design, allowing operators to easily complete the process of loading, compressing and unloading garbage. Overall, this vehicle has become a powerful assistant in urban sanitation work with its high efficiency, environmental protection, durability and humanization, and has made important contributions to the cleanliness and beauty of the city.

(1) Isuzu KV100 6cbm trash compactor truck video

(2) Isuzu T30 Explorer pickup Specifications

|

Isuzu KV100 6 cbm trash compactor truck |

||

|

Truck model |

PT5070GXZ |

|

|

Cabin |

Isuzu KV100 3X cabin,driving type 4*2 LHD,single row,2 passengers, air conditioner,USB,AC |

|

|

Overall Size(mm) |

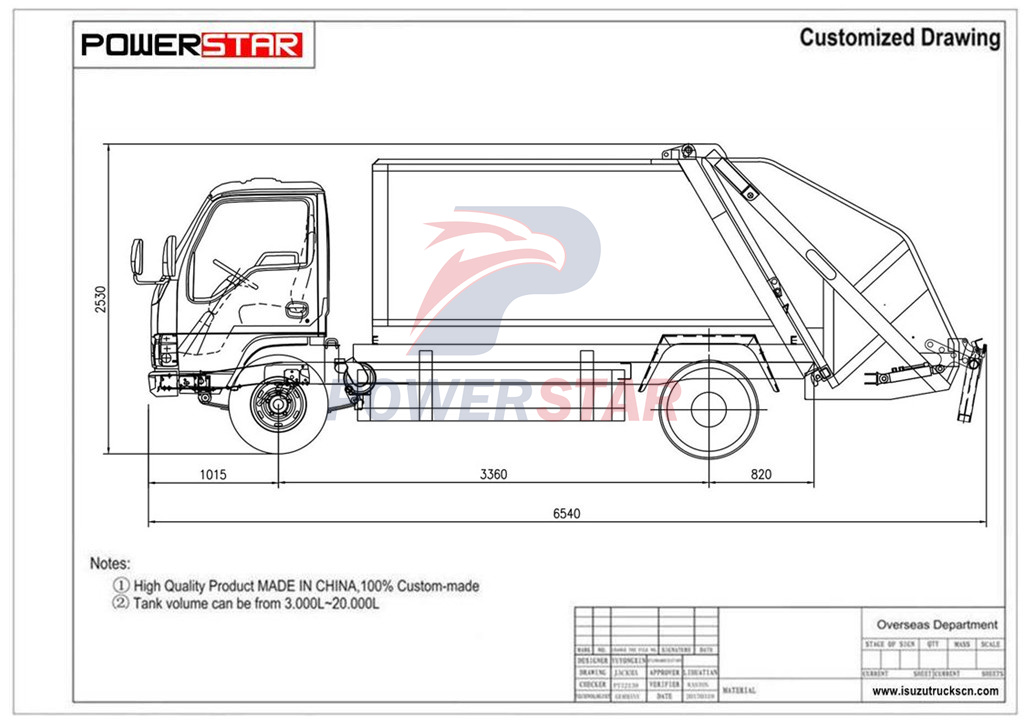

6540*2300*2480 mm |

|

|

Bin capacity(mm) |

6CBM |

|

|

Wheel base(mm) |

3360 |

|

|

GVW(kg) |

7300 |

|

|

Curb weight |

3120 |

|

|

Front axle loading capacity(kg) |

2500kg |

|

|

Rear axle loading capacity(kg) |

4800kg |

|

|

Engine |

Model |

4KH1CN6LB |

|

Type |

4-stroke direct injection,4-cylinder in-line with water cooling, turbo-charging and inter-cooling |

|

|

Hose Power(HP) |

120HP/88KW |

|

|

Displacement |

2999ml |

|

|

Emission standard |

Euro 6 |

|

|

Max speed |

110km/h |

|

|

Tire |

700R16(6+1 tire) |

|

|

Transmission |

MSB 5-speed,manual |

|

|

Superstructure |

Body capacity |

6cbm |

|

Box material |

Side 4mm,bottom 5mm |

|

|

Design |

Whole unit with Leakage Proof Design |

|

|

Sewage tank |

200 liters |

|

|

Filling work cycling time |

20~25 s |

|

|

Garbage Compact Ratio |

1/3 - 1/4 |

|

|

Discharge model |

Horizontal Ejection |

|

|

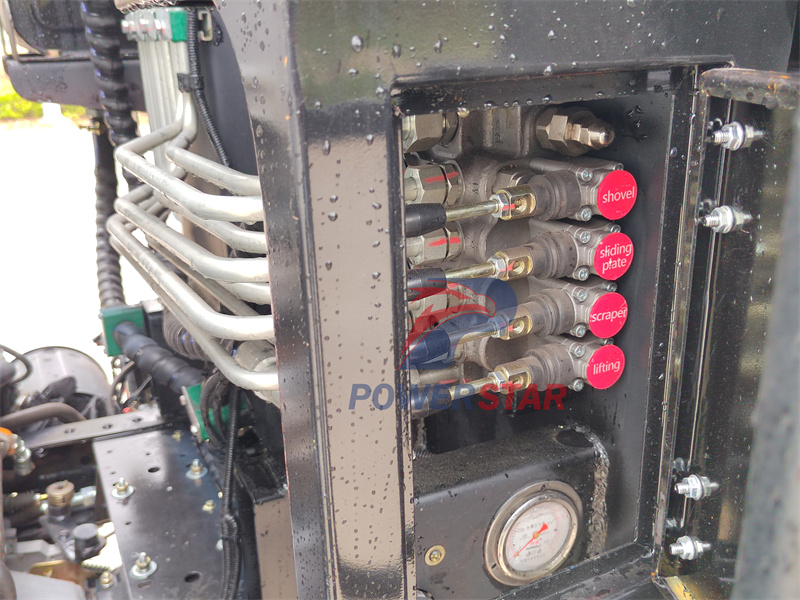

Control system |

The system is controlled from the PLC control box, which enables, start, stop, 1-cycle, continuous cycles, and rescue activities. Tailgate and ejector controls are in front of the body. All devices for loading control are mounted on the tailgate right side, and all are manual control for safety purposes. Compaction is controlled electrically via push-buttons, and manually in case |

|

|

Control panel |

English or Your language |

|

|

All standard accessories: Dust bin lifter,Ladder, warning lights, Emergency stop button,handrail, fire extinguisher, basic tool kit, English manual... |

||

|

Brake system |

Service brake: dual circuit compressed air brake Parking brake (emergency brake): spring energy, compressed air operating on rear wheels Auxiliary brake: engine exhaust valve brake |

|

|

Electrics |

Operating voltage:24V,negative grounded Batteries:2x12 V,165 Ah horn,headlamps,fog lights,brake lights,indicators and reverse light |

|

|

Optional |

** Back alarm and Camera can be equipped. |

|

II. Product Detailed Description

(3) Technical drawing of Isuzu KV100 6CBM Trash Compactor Truck

Isuzu KV100 6 cubic compression garbage truck is a special vehicle designed for urban sanitation work. It adopts advanced compression technology and automatic control system, which can realize the automatic operation of loading, compressing and unloading garbage, greatly improving work efficiency. It is an urban sanitation tool that integrates high efficiency, environmental protection, durability and intelligence.

Chassis and engine

The compression garbage truck is modified on the basis of Isuzu KV100 chassis. The number of spring leaves is 8/6+5, the number of tires is 6, and the tire specification is 7.00R16 14PR. Such chassis and tire configuration make the vehicle have better carrying capacity and driving stability.

Isuzu KV100 6 cubic compression garbage truck is equipped with Isuzu 4KH1CN6LB engine. This engine has a displacement of 2.999L, a maximum output power of 88kW, a corresponding maximum horsepower of 120 horsepower, an emission standard of National VI, and a fuel type of diesel. The engine is powerful, energy-saving and environmentally friendly, low fuel consumption, and easy maintenance, providing a solid guarantee for the stable operation of the vehicle.

The vehicle is equipped with Isuzu MSB five-speed gearbox with 5 gears. Such a gearbox configuration makes it easier to shift gears during driving, meets the different driving needs of drivers, and also improves the fuel economy of the vehicle.

Body design

The body design of Isuzu KV100 6-cubic-meter compression garbage truck adopts electromechanical and hydraulic integration technology. With the help of mechanical, electrical and hydraulic combined automatic control system, computer control and manual operation system, it realizes a series of automated operations such as garbage dumping, crushing or flattening, strong filling, compaction and unloading. The body material is WISCO high-quality carbon steel, with an effective compression volume of 6 cubic meters, PLC one-button operation control, integrated hand-light operation mode, dual electric control on both sides, and in-cab operation. The bottom plate support is strengthened, two-way compression, and the open and easy-to-clean sewage tank solves the problem of secondary pollution during garbage transportation.

(4) Truck Pictures

Trash compactor made by Isuzu trucks

Isuzu KV100 6cbm compression garbage truck

Isuzu truck with garbage compactor bodies

Isuzu 6cbm rear loader compactor truck

III.Product Details of Garbage Collection Truck:

Garbage bin composition

The garbage bin is the main part of the compression garbage truck, which is used to load and compress garbage. The garbage bin of Isuzu KV100 6-cubic-meter compression garbage truck is mainly composed of the following parts:

1. Bin: The bin of the garbage bin is welded with high-strength steel plates, which has sufficient strength and rigidity to withstand the huge pressure generated when the garbage is compressed. The shape and size of the bin are carefully designed to maximize the loading capacity and optimize the compression effect.

2. Compression mechanism: The compression mechanism is a key component in the garbage bin, which consists of steel plates, channel steel welded pressure plates, guide wheels and cylinder seats. Driven by the cylinder, the compression mechanism can efficiently compress the garbage in the hopper into the car compartment, thereby improving the loading density and transportation efficiency.

3. Sealing device: The sealing device of the garbage bin adopts advanced sealing technology to ensure that the garbage will not leak or emit odor during compression and transportation. This helps to reduce secondary pollution and protect the environment.

4. Sewage tank: A sewage tank is set at the bottom of the garbage bin to collect the accumulated water inside the car compartment and the excess water in the hopper. When unloading, the sewage in the sewage tank can be discharged automatically or manually to avoid pollution to the environment.

(5) Three control mode

Cab control buttons

Cab control buttons

Hydraulic Control Joysticks(At drive side)

Electric Control Box (In tailgate)

Working method

The working method of Isuzu KV100 6-cubic-meter compression garbage truck mainly covers three links: loading, compression and unloading. The following is the specific work process:

1. Loading: When the garbage bucket is full, the garbage bucket is flipped to the top of the garbage bin through the flipping mechanism and poured into the garbage bin. The flipping mechanism adopts hydraulic double-acting double-cylinder flipping to ensure that the flipping process is smooth and safe.

2. Compression: In the garbage bin, the compression mechanism starts to work. By operating the control switch on the multi-way reversing valve, the hydraulic oil drives the relevant cylinder to work. The cylinder drives the compression mechanism to gradually compress the garbage into the car. During the compression process, the scraper, slide plate and push plate work together to ensure that the garbage is evenly and tightly compressed.

The following Mainly steps:

· After the filling bucket is full of garbage, the compression mechanism of the vehicle starts to work.

· The slide plate drives the scraper to move downward together, insert into the garbage for crushing and initial compression.

· The scraper rotates forward to further compact the garbage.

· After the scraper is in place, it moves upward with the slide plate to compact the garbage and fill it into the garbage bin.

·During the continuous compression and filling of garbage, the push shovel overcomes the back pressure and gradually retreats under the action of the extrusion force, so that the garbage fills the entire garbage bin evenly.

3. Unloading: When unloading is required, the garbage bin is lifted to a suitable position by operating the multi-way reversing valve or the CAN electronic control box. Then, the push plate is operated to push the garbage out of the garbage bin. After unloading, the garbage bin is reset by operating the multi-way reversing valve or the CAN control box to complete the entire unloading process.

During the entire working process, the Isuzu KV100 6-cubic-meter compression garbage truck realizes the automatic operation of loading, compression and unloading of garbage through efficient compression technology and advanced automatic control systems. This not only improves work efficiency, but also reduces the consumption of manpower and material resources and reduces operating costs. At the same time, the environmental protection performance and durability of the vehicle are also fully guaranteed, making an important contribution to the cleanliness and beauty of the city.

(6) Other details

Tailgate

Push Plate Assembly

Flip mechanism

Hydraulic Cylinder

Slide Plate and scraper Hydraulic Cylinder

Advantages of use

The Isuzu KV100 6-cubic-meter compression garbage truck has the functions of automatic repeated compression and peristaltic compression, high compression ratio, good sealing, large loading capacity, convenient operation, good environmental protection, and high vehicle utilization power. The operation is automated, and the garbage collection method is simple and efficient, which greatly improves the efficiency of sanitation work and saves manpower and material resources. At the same time, the vehicle is also equipped with original air conditioning, power steering, clutch power steering, ABS anti-lock braking system, shock-absorbing seats and other humanized configurations to improve driving comfort and safety.

Features

Isuzu KV100 6-cubic-meter compression garbage truck has become a powerful assistant in urban sanitation work with its high-efficiency compression, environmental protection and energy saving, easy operation, durability and reliability, and one vehicle with multiple buckets. It has the following main features:

1. High-efficiency compression:

• The compression mechanism of the vehicle adopts advanced compression technology, which can efficiently compress the garbage, thereby increasing the loading capacity and transportation efficiency.

• High compression ratio can reduce the volume and weight of garbage and reduce transportation costs.

2. Automatic control:

• The vehicle is equipped with an advanced automatic control system, which can realize the automatic operation of loading, compressing and unloading garbage.

• Simple and fast operation reduces the work intensity of the operator.

3. Environmental protection and energy saving:

• The vehicle adopts environmentally friendly materials and advanced sealing technology to prevent garbage leakage and odor emission.

• The engine is powerful and energy-saving and environmentally friendly, reducing fuel consumption and emission pollution.

4. Durable and reliable:

• The key components of the vehicle such as the garbage bin and compression mechanism are welded with high-strength steel plates, which have sufficient strength and rigidity.

• Rigorous testing and inspection ensures the durability and reliability of the vehicle.

5. One vehicle with multiple buckets:

• The vehicle can realize the function of one vehicle with multiple buckets, that is, one vehicle can be equipped with multiple garbage buckets.

• This improves the utilization rate and work efficiency of the vehicle and reduces the waiting time during garbage collection.