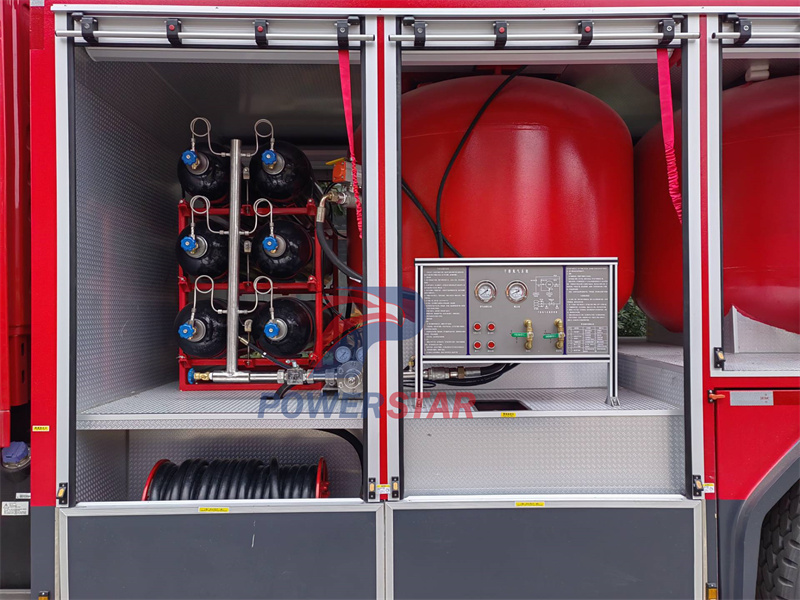

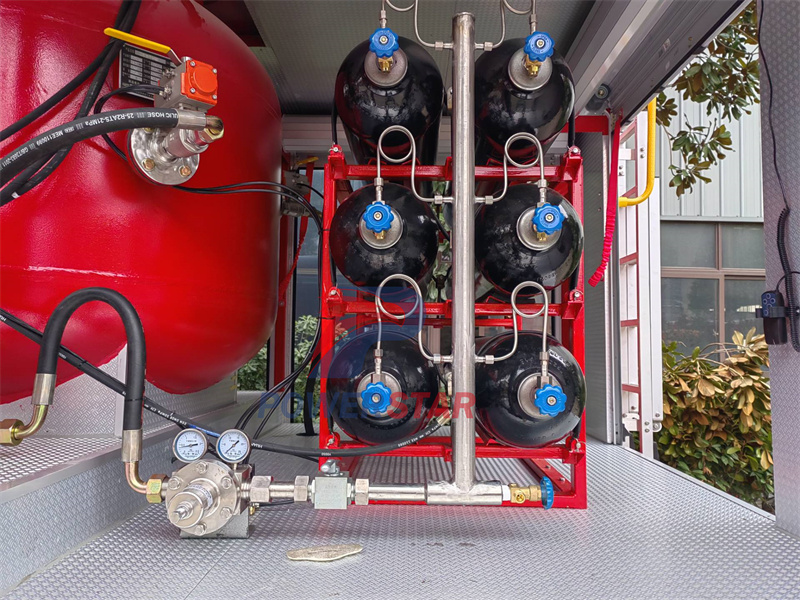

This is a dry powder nitrogen fire truck built on ISUZU GIGA Chassis. It is equipped with a powerful ISUZU 6UZ1-TCG61 engine with a displacement of 9.839L and an output power of 380 horsepower. It adopts a 6X4 drive mode and is equipped with a 12-speed gearbox. The maximum speed can reach 90km/h, which can adapt to various complex road conditions. In terms of the fire protection system, the Giga fire truck is equipped with 2 units 2,000-liter carbon steel dry powder storage tanks and 12 80-liter nitrogen cylinders with a design pressure of 15MPa. The fire pump is driven by PTO, with a pressure range of 1.6-2.5 MPa and a flow rate of 80-120 kg/s. The fire cannon has a spray speed of 60-100 kg/s and a range of 40-60 meters, which can effectively respond to various fire situations. The vehicle is also equipped with a full set of standard fire rescue equipment, such as shovels, crowbars, axes and cutting equipment, etc., and ladders and floodlights are optional.

Work capacity:

4000LTruck model:

PT5250GDXFEngine power:

380HPEngine type:

6UZ1-TCG61Axle drive:

6X4,left hand driveGear box:

FAST gearbox, manual, 12 gears forwards with 2 reverseRemarks:

4000L dry powder and nitrogenIsuzu GIGA dry powder/nitrogen fire truck is an efficient and versatile fire extinguishing equipment, which plays a key role in fires in important places. Isuzu GIGA 6x4 fire truck with dry powder/nitrogen tank combines two fire extinguishing media, dry powder and nitrogen, and its fire extinguishing principle is very comprehensive. Dry powder will melt at high temperature, forming a thin film covering the surface of the burning object, isolating oxygen and thus inhibiting combustion. Some dry powders such as sodium bicarbonate will decompose at high temperatures, releasing free radicals and interfering with the chain reaction of combustion. Nitrogen, as an inert gas, can dilute the oxygen concentration in the air to achieve the purpose of suffocation and extinguishing fire. In addition, nitrogen and dry powder absorb heat when sprayed, reduce the temperature of the burning object, and play a cooling role.

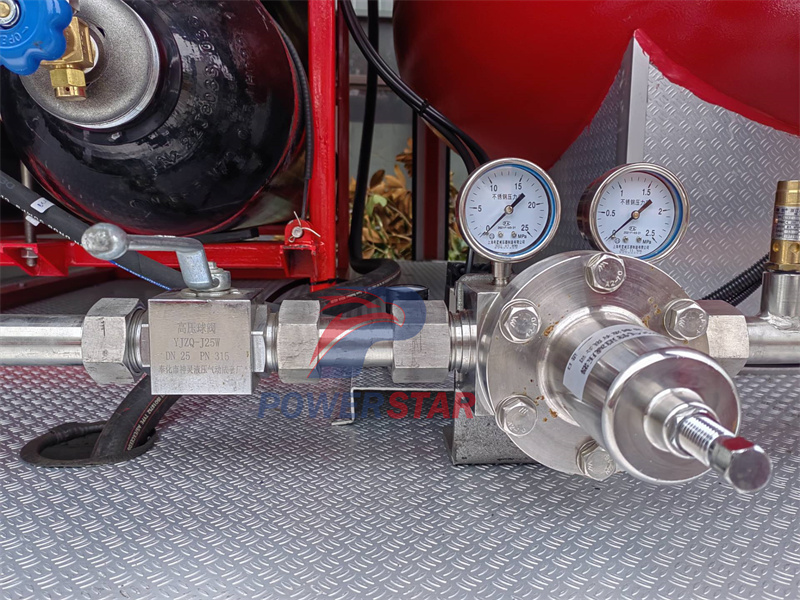

When assembling Isuzu dry powder nitrogen fire truck, several key points need to be considered. The tank system includes dry powder tanks and nitrogen tanks, and it is necessary to ensure good sealing performance and be able to withstand high pressure. The delivery system includes pipelines, valves and injection devices, and the materials must be corrosion-resistant and high-pressure resistant. The pressure control system is used to adjust the nitrogen pressure to ensure the stability of dry powder injection. The mixing device is used to fully mix the dry powder and nitrogen to improve the fire extinguishing efficiency. The control system includes long-range and short-range control devices to ensure flexible use in various situations. The main reason for the chassis selection is to ensure the mobility and stability of the whole vehicle.

Isuzu heavy-duty dry powder nitrogen fire truck plays an important role in industrial facilities such as petrochemical plants, power plants, especially in places involving flammable and explosive substances. It is also suitable for storage facilities such as large warehouses and logistics centers, especially places where flammable items are stored. Airports are used to deal with special situations such as aircraft fires, while ports are suitable for fires such as ships and containers. In small spaces such as tunnels, its fire extinguishing effect is remarkable. For forest fires, large-capacity dry powder can quickly control the spread of fire.

Isuzu GIGA dry Powder nitrogen fire truck has a fast fire extinguishing speed, and the combination of dry powder and nitrogen can quickly extinguish the flames. Secondly, it has a wide range of applications and can handle Class A, B, C fires, and even some metal fires. Furthermore, dry powder and nitrogen will not cause environmental pollution, which is an environmentally friendly fire extinguishing method. It is also suitable for extinguishing fires of live equipment and has electrical safety. Finally, compared with foam or water, dry powder is easier to clean up and the subsequent treatment is simple.

Specifications:

|

ISUZU GIGA dry powder nitrogen fire truck |

||||

|

General |

Vehicle Brand |

Powerstar |

||

|

Chassis Brand |

ISUZU |

|||

|

Overall Dimension |

19600*2670*3790mm |

|||

|

GWW/ Kerb Weight |

35,000kg/16,820kg |

|||

|

Cab |

Cab Capacity |

2+4 persons allowed |

||

|

Air Conditioner |

air conditioner |

|||

|

Engine |

Fuel Type |

Diesel |

||

|

Engine Brand |

ISUZU engine ,6UZ1-TCG61 |

|||

|

Power |

380HP(279kw) |

|||

|

Displacement |

9.839L |

|||

|

Emission Standard |

Euro 6 |

|||

|

Chassis |

DriveType |

6X4,left hand drive |

||

|

Transmission |

12-speed forward, 2 reverse |

|||

|

Wheelbase/No.of axle |

4600+1370mm/3 |

|||

|

Tyre Specification |

295/80R22.5 |

|||

|

Tyre Number |

12 tyres and 1 spare tyre |

|||

|

Max Speed |

90km/h |

|||

|

Paint |

Metallicpaint |

|||

|

Superstructure |

Dry Powder |

2,000 Litres (About 500 gallons) |

2 pcs |

|

|

TankMaterial |

carbon steel |

|||

|

Nitrogen Gas Bottle |

Material |

37Mn |

||

|

Capacity |

80Litres |

|||

|

Quantity |

12 |

|||

|

Design pressure |

15MPa |

|||

|

Fire Pump |

Drive mode |

PTO |

||

|

Pressure range |

1.6-2.5 MPa |

|||

|

Flow rate |

80-120 kg/s |

|||

|

Fire Cannon |

Flow speed |

60-100 kg/s |

||

|

Range |

40-60 m |

|||

|

All standard accessories.Typical modern fire apparatu scarries equipment for a |

||||

|

Optional |

Ladders,floodlight |

|||

Feature:

For Isuzu GIGA 6x4 heavy-duty nitrogen dry powder fire trucks, high-pressure gas driven pumps or mechanical driven pumps are usually used. The type is a multi-stage centrifugal pump or a positive pressure volumetric pump. It is usually driven by a power take-off and can be driven by an independent engine. We can customize and modify it according to customer needs. The pump body is usually made of corrosion-resistant alloys such as stainless steel or aluminum alloy. It has self-priming ability and can start quickly. The pressure is stable, the flow is adjustable, it has overload protection function, and low noise and low vibration design.

The fire cannon is divided into two, which are independent systems and can be used at the same time to speed up the fire extinguishing efficiency. Usually the electronic control panel can adjust the dry powder cannon, the rotation angle is 360° horizontally and -15° to +75° vertically. The specially designed nozzle can fully mix the dry powder and nitrogen. It has an adjustable function and can change the spray mode (such as fan-shaped, columnar). The material is a corrosion-resistant alloy such as stainless steel. A wireless remote control can also be installed to operate the electronic cannon.