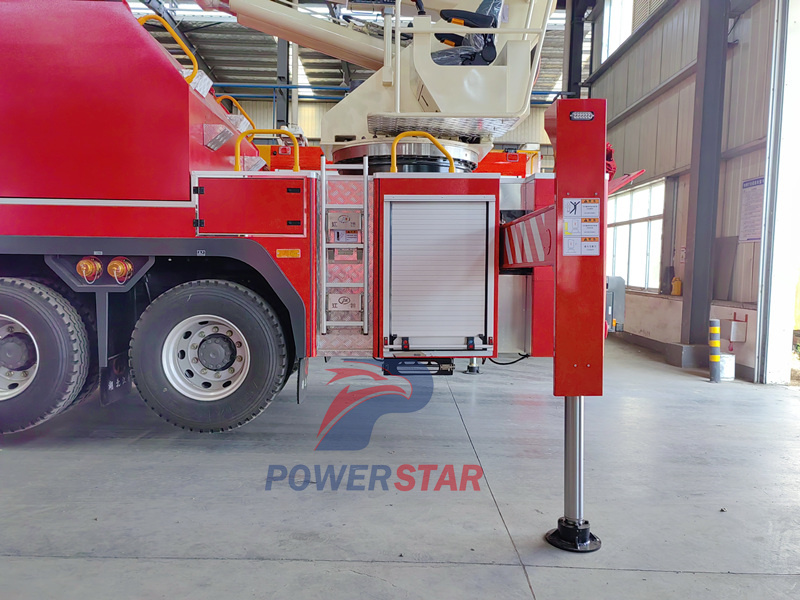

The Isuzu GIGA water & foam truck with mounted high reach extendable turret produced by Powerstar is a vehicle dedicated to fire rescue and fire fighting. The vehicle is modified on the basis of the Isuzu 6x4 GIGA chassis. The vehicle is equipped with an Isuzu 6UZ1-TCG61 380HP engine with strong power and a FAST 12-speed transmission, which has smooth shifting and efficient transmission. The vehicle is equipped with a 8-cubic-meter water tank and a 2-cubic-meter foam tank, which can be used in combination. Its CB10/100-TB fire pump and PLKD8/80 water&foam water combined fire monitor provide powerful fire fighting capabilities. The vehicle is also equipped with a series of fire fighting equipment to provide more comprehensive support.The subframe adopts a large-section box-shaped structure with good torsion resistance, the outrigger adopts a short-span H-shaped structure, and the arm adopts a folding arm combination, which moves quickly and smoothly; the slewing part is equipped

Work capacity:

10000LTruck model:

PT5250JGXFEngine power:

380HPEngine type:

6UZ1-TCG61Axle drive:

6X4,left hand driveGear box:

FAST gearbox, manual, 12 gears forwards with 2 reverseRemarks:

8000L water tank,2000L foam tankIsuzu GIGA fire water truck with mounted high reach extendable turret, boom and other related structural parts are made by making full use of our company's advanced manufacturing technology, which is efficient and reliable, and represents the international advanced level.

The truck is modified from the Chinese ISUZU GIGA heavy-duty chassis, with strong power and advanced configuration. The power take-off is the original chassis power take-off, which has the best power matching. The subframe adopts a large-section box-shaped structure with good torsion resistance, the outrigger adopts a short-span H-shaped structure, and the arm adopts a folding arm combination, which moves quickly and smoothly; the slewing part is equipped with a central slewing joint that can achieve 360-degree unlimited slewing angle.

The Isuzu GIGA water & foam truck with mounted high reach extendable turret is equipped with a large-flow fire pump and fire monitor, and the water tank and waterway are all made of high-quality stainless steel and high-strength aluminum alloy pipes. The hydraulic system adopts a high-performance pump and an electric-liquid proportional control mode. The electrical system adopts a mature and reliable controller CAN bus communication technology, and multi-point centralized operation. The body adopts a rust-proof aluminum alloy skin structure, and the equipment box adopts a rolling door structure with a large capacity. The ISUZU GIGA Fire truck has complete supporting facilities, which can conveniently absorb water from its own water tank, fire hydrant, and pond, and can also realize relay water supply. The water outlet and water injection interfaces are arranged symmetrically on the left and right of the body, which fully meets the requirements of various sites.

Specifications:

|

Item |

Unit |

Parameters |

||

|

Driving performance parameters |

Overall dimensions (length x width x height) |

mm |

10500×2540×3820 |

|

|

Maximum speed |

km/h |

90 |

||

|

Minimum turning diameter |

m |

22 |

||

|

Maximum climbing ability |

% |

40 |

||

|

Braking distance (full load, initial braking speed 30km/h) |

m |

9 |

||

|

Approach / departure angle |

° |

19/ 10 |

||

|

wheelbase |

mm |

4,600+1,370 |

||

|

Number of leaf springs |

|

4/5/5 |

||

|

Tire specifications |

|

Front wheel 385/65R22.5 Rear wheel 315/80R22.5 |

||

|

Number of tires |

|

10+1 |

||

|

Number of passengers allowed in the cab |

|

2+4 |

||

|

Quality Parameters |

Fire extinguishing agent rating Loading mass |

water |

kg |

8000 |

|

Foam |

kg |

1000 |

||

|

Curb Weight |

Vehicle |

kg |

22000 |

|

|

First Axle |

kg |

9000 |

||

|

Second Axle |

kg |

15000 |

||

|

Third Axle |

kg |

15000 |

||

|

Chassis |

Model |

|

ISUZU GIGA |

|

|

Drive System |

|

6x4 |

||

|

Engine |

Model |

|

6UZ1-TCG61 |

|

|

Displacement |

mL |

9839 |

||

|

Emission Standards |

|

Euro 6 |

||

|

Brand |

|

Isuzu |

||

|

Item |

Unit |

Parameters |

|||

|

Working performance |

Rated working height |

m |

20 |

||

|

Maximum working range |

m |

8.3 |

|||

|

Fire Pump |

Brand |

|

China top brand |

||

|

Model |

|

CB10/100-TB |

|||

|

Limited Data |

L/s |

100 |

|||

|

Preset Pressure |

MPa |

1.0 |

|||

|

Water Absorption Depth |

m |

7 |

|||

|

Water diversion time |

s |

≤85 |

|||

|

Fire cannon |

Water-foam dual-purpose cannon

|

Brand |

|

China Top Brand |

|

|

Model |

|

PLKD8/80 |

|||

|

Limited Data |

L/s |

80 |

|||

|

preset pressure |

MPa |

0.8 |

|||

|

Range |

m |

Water≥75,Foam≥70 |

|||

|

Gun head swing range (relative to the gun body in driving state) |

UP & Down |

|

-30°~+70° |

||

|

Right & Left |

|

≥340° |

|||

|

Arm |

range |

Lower arm (relative to horizontal plane) |

|

0~+80° |

|

|

Lower arm relative to upper arm |

|

0~150° |

|||

|

Boom action time (boom fully extended, amplitude changed to maximum angle, rotation to 90°) |

s |

<150 |

|||

|

Outrigger deployment time |

s |

<40 |

|||

|

Boom rotation speed |

r/min |

1~2 |

|||

|

Outrigger span (vertical × horizontal) |

mm |

5890×2150 |

|||

Feature:

Boom structure

The boom is welded from high-strength alloy steel. The boom consists of a lower boom and an upper boom. The lifting is driven by a hydraulic cylinder. The maximum operating range is 8.3 meters, 360-degree continuous rotation, the maximum working height is 20 meters, and the boom action time is <40S; the lower boom can be lifted at any angle between 0° and 80°. The lower and upper booms can be lifted at any angle between 0° and 150°.

Turntable structure

The slewing mechanism is completed by a hydraulic motor driving a worm gear, which makes the rotation smooth and self-locking; the luffing mechanism is realized by an optimized combination of the luffing hydraulic cylinder, the luffing balance valve and the two-way hydraulic lock, and its characteristics are good luffing synchronization and strong safety.

Center rotation body

The central rotating body is used to realize the connection of hydraulic pressure, electric circuit and water circuit for getting on and off the vehicle, so as to avoid the damage of hydraulic pipeline, electric circuit and water circuit caused by the rotation of turntable and arm.

Electric remote control fire cannon

The fire cannon is manufactured by a well-known Chinese brand and uses a manual fire cannon for both water and foam.

1) Model: PLKD8/80.

2) Material: The cannon head is made of aluminum alloy and the cannon body is cast iron.

3) Fire cannon flow rate: 0-4800L/min; rated pressure ≤1.0MPa.

4) Range: water range ≥75 meters, foam range ≥70 meters;

5) Rotation angle: horizontal rotation angle 0 degrees ~ 340 degrees, elevation angle -30 degrees ~ +70 degrees;

Fire Pump System

The fire pump is produced and provided by a well-known Chinese brand, model CB10/100-TB, displacement 6000 liters per minute; water absorption depth greater than 7 meters; water diversion time less than 50 seconds; equipped with a computer automatic voltage stabilizing device with advanced technical performance. Automatic foam proportion mixer: mixing ratio 1%~10%.

Water system

The pipeline of the fire protection system is stainless steel pipeline + aluminum alloy pipeline. The water pipe reaches the upper vehicle through the central rotating body, which can meet the needs of water supply or foam. There is an electric remote-controlled water cannon at the upper arm head, which can change the water flow form (straight and water splash), and can spray water or foam. There is a water inlet at the bottom of the vehicle to meet the large flow fire extinguishing requirements of high-rise buildings.

1) Water control mode: electric control pneumatic;

2) Control panel location: rear of the vehicle body;

3) Stainless steel pipeline is used for getting off the vehicle;

4) Aluminum alloy water pipe + rubber steel wire hose is used for getting on the vehicle.

5) The configuration of fire water outlet is as follows:

|

Connection |

Size |

Valve |

Position |

|

Outlet water interface

|

6× DN80 |

Handwheel ball valve with interface |

3 units on each side of the vehicle body This interface can also be used as an external water supply interface |

|

External water suction interface |

2× DN150 |

Manual Butterfly Valve |

Rear side of vehicle |

|

From water tank to pump suction port |

1× DN150 |

Pneumatic Butterfly Valve |

Pump room |

|

Pump to water tank filling port |

1× DN80 |

Pneumatic Butterfly Valve |

Pump room |

|

Upper muzzle |

1× DN100 |

Pneumatic Butterfly Valve |

Pump room |

|

Foam tank foam outlet |

1× DN50 |

Pneumatic Butterfly Valve |

Pump room |

|

External suction foam interface |

1× DN50 |

Handle ball valve with interface |

Body side |

|

External foam interface |

1× DN50 |

Handle ball valve with interface |

Body side |

|

Water tank filling interface |

4× DN80 |

Interface with blind cover |

2 units on each side of the vehicle |

|

Water tank drain |

1× DN50 |

Handle ball valve |

Body side |

|

Foam tank drain outlet |

1× DN50 |

Handle ball valve |

Body side |

|

Water supply/outlet connection type: standard is card type (quick), inner buckle type is optional. Water suction pipe interface type: card type (quick). In cold areas, it is recommended to use inner buckle type interface. |

|||

Liquid tank

1) Water/foam capacity: 8000L/1000L.

2) The tank body is elastically connected and installed with the auxiliary beam.

3) The tank body is made of stainless steel, with excellent anti-corrosion performance, never rusting and leaking.

4) The tank body is equipped with vertical and horizontal anti-sway plates, and the internal maintenance manhole is convenient for entry and exit; the tank top plate is treated with anti-slip technology.

5) The tank body has 3 manholes, with a diameter of 500mm, with quick locking and opening devices. The tank body automatically releases pressure when the pressure exceeds 2 kg. The water tank cover is painted green and the foam tank cover is painted yellow; the water tank is equipped with a DN80 overflow pipe with an overflow cap device, and a liquid level and low liquid level integrated sensor; the foam tank is equipped with a DN80 overflow foam pipe with an overflow cap device and a liquid level sensor; 2 residual liquid discharge ports, 1 for the water tank and 1 for the foam tank, with a ball valve; 4 water inlets (2 DN80 on each side of the vehicle are connected to the DN100 pipeline).

6) The manhole cover is cast from aluminum alloy. The water pump system pipes and manhole covers are painted in different colors according to the highest Chinese standards. The water tank cover is painted green and the foam tank cover is painted yellow to facilitate fault maintenance and operation warnings.

Hydraulic system

1) The vehicle mainly uses high-performance hydraulic system components, which are divided into the onboard and offboard hydraulic systems. The offboard hydraulic system is composed of a fuel tank, a hydraulic pump, a one-way valve, an offboard leg control valve and an emergency system. The offboard control valve-the main reversing valve controls the extension and retraction of the legs. The onboard hydraulic system uses an electro-hydraulic proportional valve. The proportional valve is a high-performance imported well-known brand with a pressure compensator, with good micro-motion performance and no heat generation in the system. When the boom moves, the engine speed automatically rises to the rated speed. The balance valve uses a well-known brand valve with good sealing performance and smooth movement.

2) The hydraulic system uses two large-capacity hydraulic oil filters to ensure the cleanliness and durability of the hydraulic oil. The hydraulic oil uses a branded anti-wear hydraulic oil or low-condensation hydraulic oil, which is anti-emulsification, consumes less additives, and has a high viscosity-temperature index. All pipe joints and hydraulic hoses are internationally renowned brand products with high pressure resistance and vibration resistance. The hydraulic steel pipe uses a precision-drawn seamless phosphated steel pipe with good anti-rust performance.